工作原理:

The work principle:

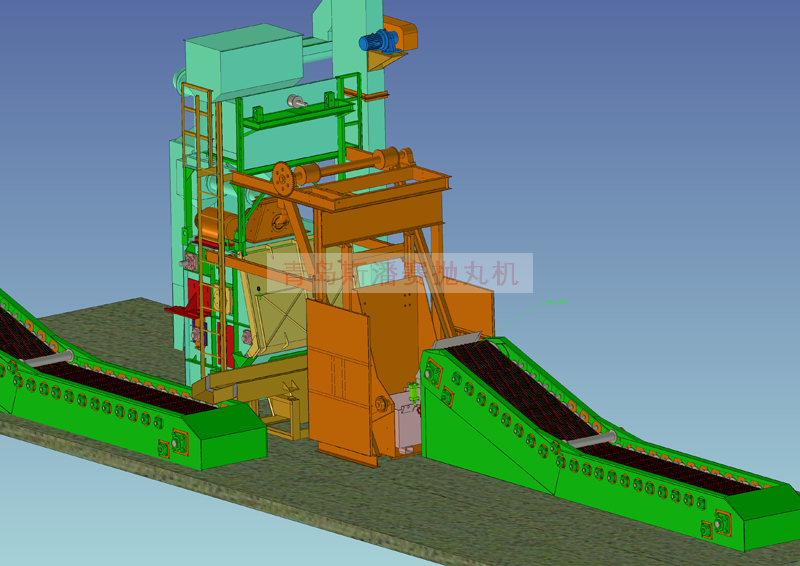

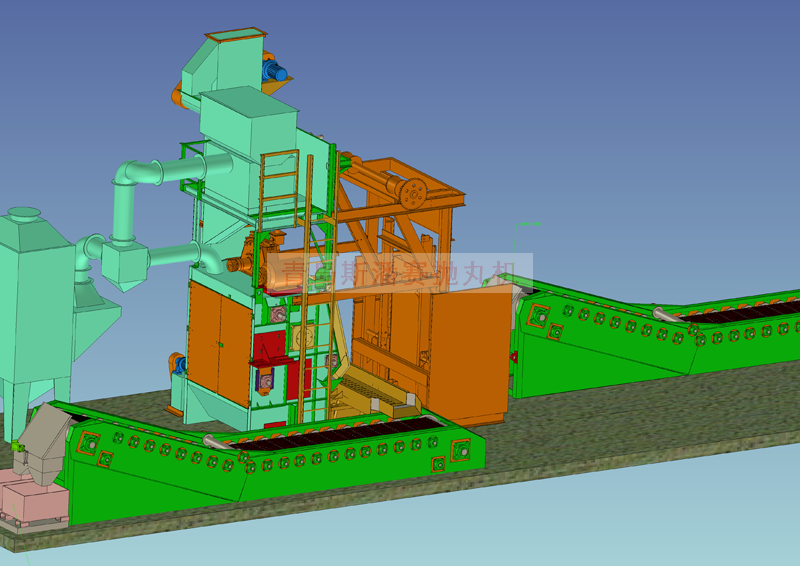

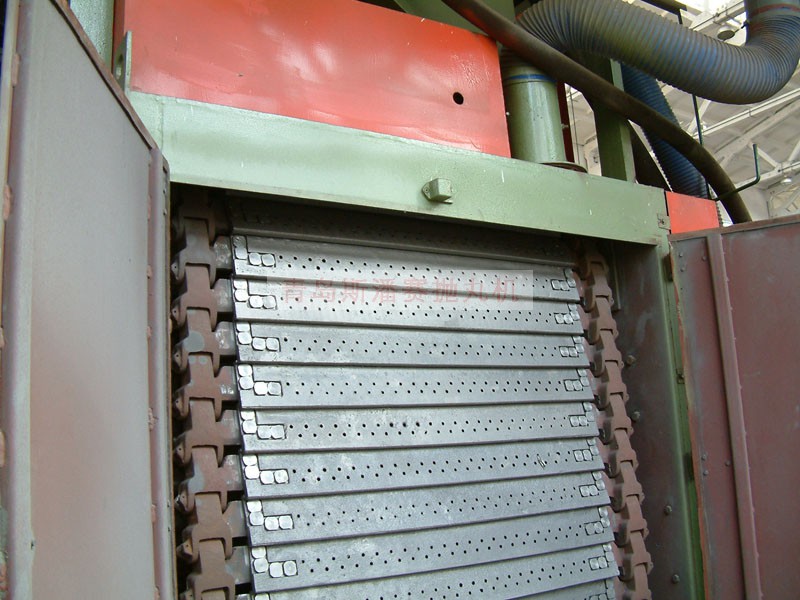

在清理仓内加入规定数量的工件后,大门关闭,机器启动,工件被滚筒带动,开始翻转,同时抛丸器高速抛出的弹丸形成扇形束,均匀地打击在工件表面上,从而达到清理的目的。抛出的弹丸及砂粒从履带上的小孔,流入底部的螺旋输送器上,经螺旋输送器送入提升机内,由提升机提到分离器中进行分离。含尘气体由风机吸送到除尘器中过滤后,变为清洁空气,排入大气中,灰尘经空气反吹落入除尘器底部的集尘箱中,用户可定期清除。废砂由废料管流出,用户可回用。丸砂混合物由回用管回收进入室体,待分离器分离后再回用

The work principle: Putting some workpieces in the cleaning-room,after the machine start,the workpieces are overturned by the moving pedrail,meanwhile,the pills,be shot off rapidly,shapes pill-lines,and hits on surface of the workpiece equably,and to clean them. The pills and sand shot off flow into the bottom-sifter through some lacunule on the pedrail,then, it is transported into elevator by screw router,finally,the elevator transports it into separator and separate. The dust ,comes from cleaning-room and separator,is sponged in the dust catcher,and fresh air is let into the air. The dust klings on the hop-pocket is fetch dawn into the collecting-dust box at the bottom of the dust catcher,for vibration of mechanism,so user may clean it out termly. the useless sand flows out through the waste pipe,and user may reuse it. The mixture of pill and sand is taken back into the chamber,and may reuse after being separated by separater. The clean pills flows into the pill-caster to hit workpieces through the electromagnetic flash-lock.

抛丸器的布置经过计算机三维动态模拟,所有布置的角度、位置均由计算机设计确定。在照顾所有需清理工件的基础上,尽量减少弹丸的空抛,从而最大限度地提高了弹丸的利用率,减少了对清理室内防护板的磨损。

The shot blast cabin and the arrangement of the shot blast unit are designed by Computer 3d dynamic simulation. Let the abrasive shoted out coverage of workpiece surface covered accurately,and the abrasive from different direction

shot to different surface of the work piece.and reduce the abrasion with shade plate.

详细技术参数表

型 号 参 数 | 橡胶履带式抛丸清理机 | 金属履带式抛丸清理机 | |||||||

SPC326 | SPC326C | SPCW3210 | SPCW3210C | SPC15GN | SPC28GN | ||||

端盘直径 | 600 | 600 | 1000 | 1000 | 1092 | 1245 | |||

端盘间距 | mm | 800 | 800 | 1100 | 1100 | 1245 | 1778 | ||

单件重 | kg | 10 | 10 | 30 | 30 | 50 | 50 | ||

通过速度 | m/min | 0.5-2 | 0.5-2 | 0.5-2 | 1-3 | 1-3 | |||

工作容积 | M3 | 0.11 | 0.11 | 0.4 | 0.4 | 0.43 | 0.79 | ||

装载量 | kg | 200 | 200 | 600 | 600 | 1360 | 3500 | ||

抛丸功率 | kw | 5.5-7.5 | 5.5-7.5 | 11-15 | 11-25 | 22-30 | 2*22 | ||

抛头数量 | 套 | 1 | 1 | 1 | 1 | 1 | 2 | ||

弹丸分离量 | Kg/min | 100-150 | 100-150 | 200-250 | 200-250 | 300-480 | 600 | ||

开门形式 | 手动侧开 | 气动向上 | 手动侧开 | 气动向上 | 电动向上 | 电动向上 | |||

上料方式 | 手动 | 手动 | 手动 | 自动 | 自动 | 自动 | |||

卸料方式 | 料框 | 料框 | 料框 | 震动输送 | 震动输送 | 震动输送 | |||

设备的主要外形尺寸 | |||||||||

外形尺寸(L*W*H) | mm | 1800/1685/3300 | 1800/1685/3300 | 3700/3500/5000 | 3700/3500/5000 | 4600/3300/5700 | 5250/3300/6885 | ||

设备功率 | kw | 12.6 | 12.6 | 27.6 | 32.6 | 41.8 | 62.2 | ||

除尘风量 | M3/h | 2200 | 2200 | 3500 | 3500 | 5300 | 6700 | ||